What Experts Say About TCS-10’s Reliability

The TCS-10 has established itself as a highly reliable component in industrial CAN-bus networks according to industry experts. Its proven performance in mission-critical applications stems from robust engineering, comprehensive redundancy features, and exceptional error handling capabilities. Engineers and system integrators consistently highlight the device’s stability in challenging environments and its ability to maintain network integrity even under extreme conditions. For organisations requiring dependable fieldbus solutions, the TCS-10 represents a trustworthy choice backed by extensive technical expertise and real-world performance.

Understanding the importance of reliability in CAN-bus networks

In modern industrial settings, CAN-bus networks serve as the critical communication backbone that connects various control systems, sensors, and equipment. The reliability of these networks is not simply a technical specification—it’s an operational necessity that directly impacts productivity, safety, and cost-efficiency.

CAN-bus (Controller Area Network) technology was originally developed for automotive applications but has since become essential in industrial automation, manufacturing, and heavy machinery. These networks must transmit time-sensitive data with absolute consistency, often in environments where failure is not an option.

When evaluating network components like switches and bridges, reliability factors become paramount. Even momentary communication disruptions can trigger emergency shutdowns, create production bottlenecks, or compromise safety systems. This is why expert assessment of devices like the TCS-10 carries significant weight—these evaluations reflect performance under real-world conditions where theoretical specifications meet practical demands.

Industry specialists emphasise that reliability in CAN networks encompasses several dimensions: hardware durability, signal integrity, error management capabilities, and long-term stability. The TCS-10 addresses these requirements through purpose-built design choices that prioritise dependable operation in industrial settings.

What makes the TCS-10 stand out for reliability?

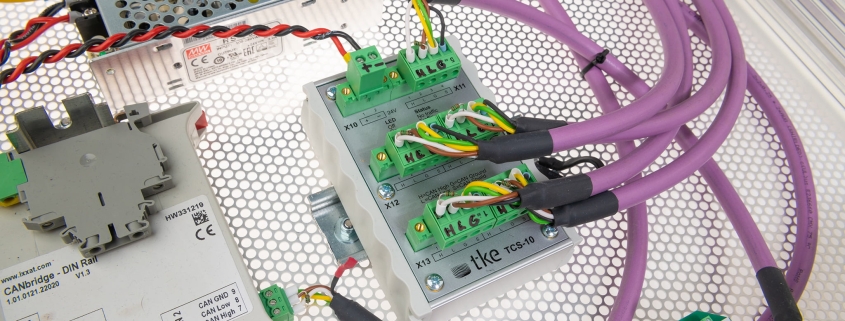

The TCS-10’s reliability stems from several key technical characteristics that work together to ensure continuous, error-free operation. Experts point to its comprehensive redundancy capabilities as a primary factor in its dependable performance.

The device incorporates dual power inputs with automatic switching, ensuring network communication continues uninterrupted even if one power source fails. This redundancy extends to its network architecture as well, with the ability to create ring topologies that maintain connectivity even when a cable connection is compromised.

Error handling represents another critical reliability feature. The TCS-10 monitors network traffic continuously and employs sophisticated algorithms to detect and manage communication issues before they escalate into system failures. This proactive approach to error management helps prevent the cascade effect where minor issues can quickly compound into major system failures.

The physical construction also contributes significantly to reliability. Engineered with industrial-grade components, the TCS-10 features robust housing designed to withstand vibration, impact, and temperature fluctuations. Industry specialists note that this mechanical durability provides essential protection for the sensitive electronic components inside.

Technical experts also highlight the device’s intelligent traffic management capabilities. By efficiently handling message prioritisation and network segmentation, the TCS-10 helps prevent network congestion that could otherwise lead to dropped messages or timing issues in critical applications.

How does the TCS-10 perform in challenging industrial environments?

Industrial environments often present extreme conditions that can compromise the performance of electronic components. The TCS-10 has demonstrated exceptional resilience in these challenging settings, according to engineering specialists who evaluate fieldbus solutions.

In high-vibration environments like manufacturing floors, mining operations, and mobile equipment, the TCS-10 maintains signal integrity and connection stability. Its robust mechanical design and secure connection interfaces prevent the intermittent connectivity issues that plague less rugged devices when subjected to continuous vibration.

Temperature fluctuation presents another significant challenge in industrial settings. Experts note that the TCS-10’s wide operating temperature range allows it to function reliably in both cold storage facilities and hot manufacturing environments without performance degradation. This thermal stability is crucial for applications where equipment must operate outdoors or in facilities with minimal climate control.

Continuous operation scenarios provide perhaps the most demanding test of reliability. In 24/7 production environments where system downtime translates directly to financial loss, the TCS-10 has established a reputation for sustained performance without requiring frequent maintenance interventions or replacements.

Electrical noise immunity represents another essential performance characteristic in industrial settings. The TCS-10’s shielding and filtering capabilities help maintain clean signal transmission even in environments with high electromagnetic interference from motors, drives, and power distribution systems.

What do system integrators say about TCS-10 implementation?

System integrators who work directly with industrial automation and control systems offer valuable perspectives on the TCS-10’s practical implementation. Their hands-on experience highlights several key advantages that contribute to the device’s reputation for reliability.

The straightforward configuration process receives consistent praise from integration specialists. The TCS-10 offers intuitive setup options that reduce the likelihood of implementation errors that could compromise system reliability. This ease of configuration means less time spent troubleshooting during commissioning and fewer potential points of failure.

Compatibility with existing systems represents another critical factor for successful integration. The TCS-10 adheres to industry standards while offering flexible configuration options, allowing it to work seamlessly with diverse equipment from various manufacturers. This interoperability eliminates many of the communication challenges that can undermine network reliability in mixed-vendor environments.

Long-term stability after implementation is perhaps the most meaningful measure of reliability. System integrators report that the TCS-10 requires minimal intervention after initial setup, with consistent performance over extended operational periods. This stability translates directly to reduced maintenance requirements and higher overall system availability.

Documentation quality and technical support availability also contribute significantly to successful implementation. Clear, comprehensive documentation helps ensure proper installation, while responsive technical support provides critical backup when challenging integration scenarios arise.

How does TCS-10’s reliability compare to other CAN solutions?

When evaluating CAN-bus network components, reliability comparison becomes a critical decision factor. The TCS-10 distinguishes itself in several key areas compared to typical alternatives available in the industrial automation market.

In terms of hardware durability, the TCS-10 demonstrates exceptional resilience compared to standard commercial-grade network devices. Its industrial-focused design provides substantial advantages in harsh operating environments where consumer or light commercial equipment often fails prematurely.

Network redundancy capabilities represent another area where the TCS-10 excels compared to basic CAN solutions. While many entry-level devices offer limited or no redundancy features, the TCS-10’s comprehensive approach to redundant power and connectivity provides significantly higher reliability in mission-critical applications.

Diagnostic capabilities also factor prominently in reliability comparisons. The TCS-10 offers enhanced visibility into network performance and potential issues, allowing for proactive maintenance rather than reactive troubleshooting after failures occur. This diagnostic depth represents a meaningful advantage over simpler CAN bridges with limited monitoring capabilities.

Performance consistency under varying load conditions represents another distinguishing characteristic. Where some network components show degraded performance during peak traffic periods, the TCS-10 maintains consistent message handling even when the network approaches capacity limits.

Key takeaways: Why experts recommend the TCS-10 for mission-critical applications

The consensus among technical specialists points to several definitive reasons why the TCS-10 stands as a preferred solution for applications where reliability cannot be compromised. These key factors form the foundation of expert recommendations for mission-critical CAN-bus implementations.

The comprehensive approach to redundancy tops the list of reliability advantages. By addressing potential failure points at multiple levels—power supply, network connectivity, and internal components—the TCS-10 provides the fault tolerance necessary for systems that must maintain continuous operation.

Environmental resilience represents another crucial factor for Scandinavian customers, who often operate equipment in challenging conditions including extreme temperatures, high humidity, and industrial environments with significant electrical noise. The TCS-10’s proven performance in these demanding settings makes it particularly well-suited for Nordic industrial applications.

The balance of sophisticated capabilities with straightforward implementation also features prominently in expert assessments. Advanced functionality provides little value if it creates implementation complexity that introduces new reliability risks. The TCS-10 delivers powerful features while maintaining accessibility for integrators and maintenance personnel.

For organisations operating mission-critical systems where downtime carries significant operational or safety implications, the TCS-10 offers the reliability foundation necessary for confidence in network performance. By combining robust hardware engineering with intelligent traffic management and comprehensive redundancy, it addresses the full spectrum of reliability requirements in industrial CAN-bus applications.

When evaluating fieldbus solutions for critical industrial applications, the TCS-10’s reliability credentials make it worthy of serious consideration, particularly for operations where consistent performance under challenging conditions is non-negotiable.

Interested in real-world automation solutions?

Browse our case studies to discover how we support safe and efficient operations through smart control and networking systems

MARIN

MARIN