Can TCS-10 Improve Performance in Harsh Environments?

The TCS-10 CAN switch bridge is specifically designed to improve performance in harsh environments through its robust construction and specialised features. Its wide operating temperature range (-40°C to +85°C), resistance to vibration, and protection against electromagnetic interference make it ideal for demanding industrial applications. The device maintains reliable communication in challenging conditions where standard equipment would fail, ensuring continuous operation of critical systems in manufacturing, transportation, mining, and outdoor installations.

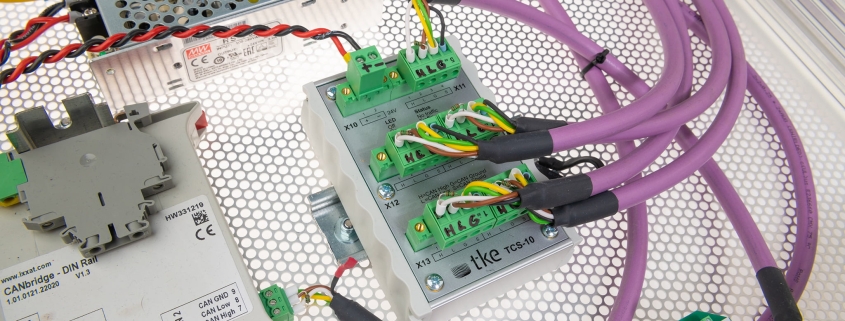

Understanding TCS-10: A solution for challenging environments

The TCS-10 is a specialised CAN switch bridge developed to address the communication challenges faced in industrial environments where standard equipment struggles to perform. At its core, the TCS-10 facilitates reliable data transmission across CAN-bus networks in conditions that would typically compromise signal integrity.

Industrial operations increasingly rely on seamless communication between various components and systems. When these communication pathways fail due to environmental factors, the consequences can range from minor inefficiencies to complete system shutdowns, resulting in costly downtime and potential safety hazards.

The TCS-10 bridges this reliability gap by providing a robust solution that maintains network performance even when subjected to temperature extremes, physical stress, moisture, dust, and electrical interference. Its design principles focus on durability without compromising on functionality, making it an essential component for industries operating in non-ideal conditions.

By ensuring consistent communication regardless of environmental challenges, the TCS-10 helps maintain operational continuity and protect critical industrial processes from environmental disruptions.

What makes an environment ‘harsh’ for industrial communication systems?

Harsh environments in industrial contexts are characterised by conditions that place extreme stress on electronic components and communication systems. These challenging settings feature one or more factors that can compromise the reliability and functionality of standard equipment.

Extreme temperatures represent one of the most common challenges, with industrial environments often experiencing either very cold conditions (below -20°C) or excessive heat (above 60°C). Both extremes can affect electronic components, causing failure or signal degradation.

Physical stressors also define harsh environments, including:

- Constant or intermittent vibration from machinery

- Mechanical shock from equipment operation

- High humidity or direct moisture exposure

- Dust, dirt, and particulate matter

Electrical challenges further complicate industrial communications:

- Electromagnetic interference (EMI) from nearby equipment

- Power fluctuations and surges

- Radio frequency interference

- Ground potential differences across large installations

Standard communication equipment often fails in these conditions because conventional designs prioritise cost-efficiency and performance under normal conditions rather than resilience. Components may overheat, connections can loosen due to vibration, moisture can cause short circuits, and electrical noise can corrupt data signals.

These factors create a significant challenge for maintaining reliable fieldbus networks in industrial settings, particularly for CAN-bus systems that require consistent signal integrity to function properly.

How does the TCS-10 maintain reliability in extreme temperatures?

The TCS-10 maintains exceptional reliability across extreme temperatures through its industrial-grade design and component selection. Engineered to operate seamlessly within a temperature range of -40°C to +85°C, it significantly outperforms standard communication equipment that typically functions within much narrower parameters.

At the hardware level, the TCS-10 incorporates temperature-resistant components specifically selected for their thermal stability. These include:

- High-quality capacitors rated for extended temperature ranges

- Temperature-stable oscillators to maintain accurate timing

- Industrial-grade semiconductors with enhanced thermal characteristics

- Circuit board materials designed to withstand thermal expansion and contraction

The device’s thermal management design contributes significantly to its temperature resilience. Its architecture includes proper component spacing and layout to facilitate heat dissipation, preventing localised hot spots that could compromise reliability.

In cold environments, the TCS-10 continues to function where standard equipment would become brittle or cease working altogether. Its components remain operational even when subjected to the freezing conditions common in outdoor installations, cold storage facilities, or winter operations in northern climates.

For high-temperature environments such as engine compartments, industrial processing areas, or sun-exposed outdoor installations, the TCS-10’s thermal management capabilities prevent overheating and maintain signal integrity even during prolonged exposure to elevated temperatures.

Can the TCS-10 withstand vibration and physical stress?

Yes, the TCS-10 is specifically engineered to withstand significant vibration and physical stress through its robust mechanical design and construction. This resilience makes it particularly suitable for installations in mobile machinery, manufacturing equipment, and transportation systems where constant movement and vibration are unavoidable.

The mechanical durability of the TCS-10 stems from several key design elements:

- A reinforced housing that protects internal components from external forces

- Secure mounting options that prevent the device from working loose over time

- Vibration-resistant soldering and component attachment methods

- Board-level reinforcement to prevent flexing under stress

- Shock-absorbing design elements that buffer sudden impacts

Connection points, often the first failure points in vibration-rich environments, receive special attention in the TCS-10 design. The device features robust connectors and terminal blocks designed to maintain reliable electrical contact even when subjected to continuous vibration.

The compact form factor of the TCS-10 also contributes to its physical resilience. By minimising the device’s size and weight while maintaining structural integrity, the design reduces the potential for movement-induced stress on components and connections.

These physical durability features ensure the TCS-10 maintains network performance integrity in applications like construction equipment, factory automation systems, railway installations, and other environments where movement and vibration would typically compromise standard communication devices.

How does TCS-10 protect against electrical interference?

The TCS-10 employs multiple layers of protection against electrical interference, ensuring reliable communication even in electrically noisy environments. Its comprehensive approach to electrical resilience addresses the various forms of interference commonly found in industrial settings.

At the heart of this protection is the TCS-10’s superior galvanic isolation capability. This feature effectively separates circuit sections, preventing ground loops and common-mode noise from disrupting communication. The isolation barrier blocks unwanted current paths while still allowing the desired signals to pass through, maintaining data integrity across electrically noisy environments.

Additional electrical protection features include:

- Advanced filtering to remove noise from power and signal lines

- Transient voltage suppression to protect against power surges

- Electromagnetic compatibility (EMC) design principles throughout

- Shielding to block external electromagnetic radiation

- Common-mode rejection circuitry to eliminate shared noise

The TCS-10’s power supply section incorporates stabilisation and filtering elements that ensure clean power delivery to sensitive components, even when the input power fluctuates or contains noise. This prevents power-related issues from affecting signal integrity.

For signal transmission, the device employs differential signalling techniques that inherently reject common-mode noise. This approach ensures that electrical interference affecting both signal lines equally is cancelled out, preserving the integrity of the transmitted data.

These electrical protection features make the TCS-10 particularly valuable in environments with numerous electrical motors, power switching equipment, radio transmitters, or other sources of electromagnetic interference that would typically disrupt industrial communication systems.

Key takeaways: Maximising performance with TCS-10 in challenging conditions

The TCS-10 CAN switch bridge delivers exceptional performance in harsh environments through its comprehensive design approach addressing temperature extremes, physical stress, and electrical interference. These capabilities translate into tangible business value through increased uptime, reduced maintenance needs, and enhanced operational reliability.

When deploying the TCS-10 in challenging conditions, consider these best practices to maximise its effectiveness:

- Position the device away from direct heat sources when possible, despite its high temperature tolerance

- Utilise proper mounting techniques to take full advantage of its vibration resistance

- Implement appropriate cable shielding and grounding to complement the device’s electrical protection

- Consider redundant communication paths for mission-critical applications

- Follow recommended maintenance schedules, even though the TCS-10 requires minimal attention

The business value of implementing reliable CAN-bus solutions like the TCS-10 extends beyond simple functionality. Organisations benefit from:

- Reduced costly downtime in production environments

- Lower maintenance and replacement costs for communication infrastructure

- Extended equipment lifespan in challenging conditions

- Improved data integrity leading to more reliable system operation

- Simplified network architecture through dependable communication bridges

By providing consistent network performance in environments where standard equipment would fail, the TCS-10 enables organisations to expand their operations into more challenging environments without compromising on communication reliability. This capability proves particularly valuable in industries like manufacturing, transportation, agriculture, and outdoor installations where environmental conditions cannot be easily controlled.

The TCS-10 represents a specialised solution for maintaining industrial communication integrity in the face of environmental challenges, delivering reliability where it matters most.

Interested in real-world automation solutions?

Browse our case studies to discover how we support safe and efficient operations through smart control and networking systems

MARIN

MARIN