CANtrace Help

A powerful CAN bus analyser software and diagnostic tool

A powerful CAN bus analyser software and diagnostic tool

The DBC file format is a CAN database file that describes the messages and signals in a CAN network. It is a text file that contains messages, signals, attributes and comments which are linked to each other through IDs or names.

DBC is a proprietary format created by Vector Informatik GmbH. This format is widely used in industry and is considered a de facto standard. CANtrace supports editing/associating DBC files to the channel you are listening to. This chapter describes how to use DBC files in CANtrace.

With CANtrace you can associate database files to the configured software channels. Data interpretation provided by the database is now available on the Send, Data and Graph tabs.

Click here to see how to set up software channels.

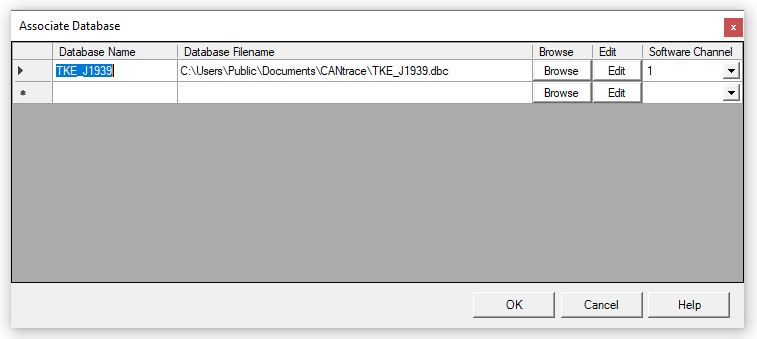

Select File > Associate Database or press the DB button (depicted below) on the main toolbar to open the Associate Database window, Figure 3.1.

![]()

Click Browse on the first empty row. Navigate to the desired database file and click Open.

Select a channel from the Software Channel drop-down box. The default channel is 1.

A database can be manually edited by clicking Edit. This opens the Kvaser Database Editor which comes bundled with CANtrace.

To remove a database, first highlight the corresponding row by left-clicking on the cell in the leftmost column. Then either press the Delete key on your keyboard or right-click on the same cell and select Remove Database.

Click OK to close the Associate Database window.

Figure 3.1 Associate Database

Note: CANtrace does not validate the consistency/correctness of the associated database(s). Erroneously configured messages and signals will get a bad interpretation in the Trace window. It is recommended to check your database file’s consistency before using it. If you are using Vector CANdb++ Editor, select File->Consistency Check.

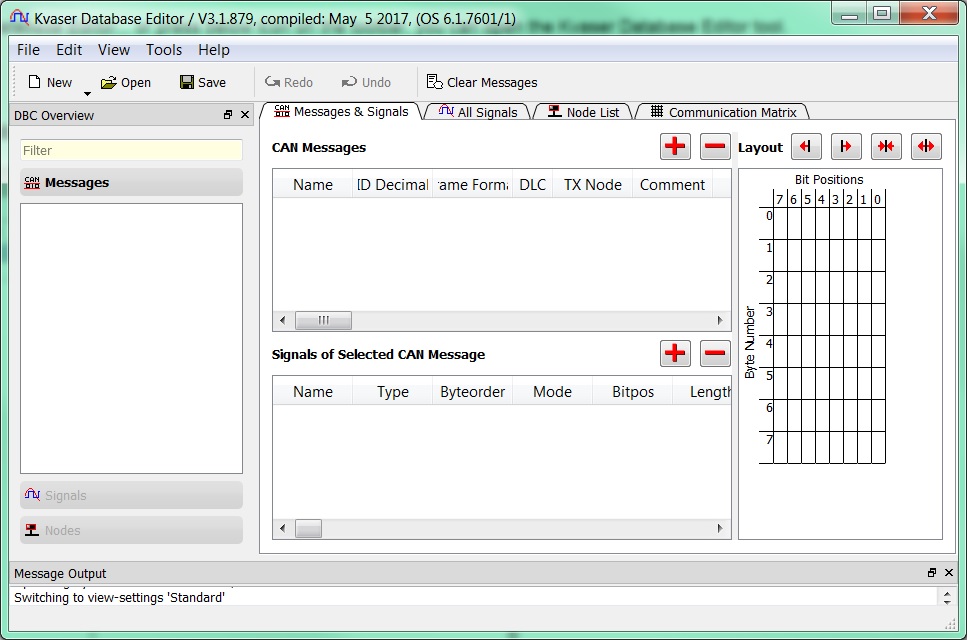

The Kvaser Database Editor which is made by Kvaser, is embedded to CANtrace. It will be installed when you install CANtrace. But it will not be removed if you uninstall CANtrace. You need to remove Kvaser Database Editor manually from Control Panel if you want.

By selecting the menu File > Database Editor or by pressing the Database Editor button on the toolbar (depicted below), you can open the Kvaser Database Editor tool.

![]()

Refer to the built-in help documentation inside Kvaser Database Editor (menu Help > Contents) to learn how to add/remove/edit CAN messages and signals.

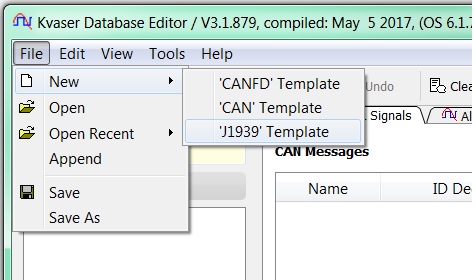

If you want to create a J1939 DBC file, click on menu File > New > J1939 Template in Kvaser Database Editor (version 3 and newer):

Figure 3.2 Create J1939 DBC using template

Figure 3.3 Kvaser Database Editor

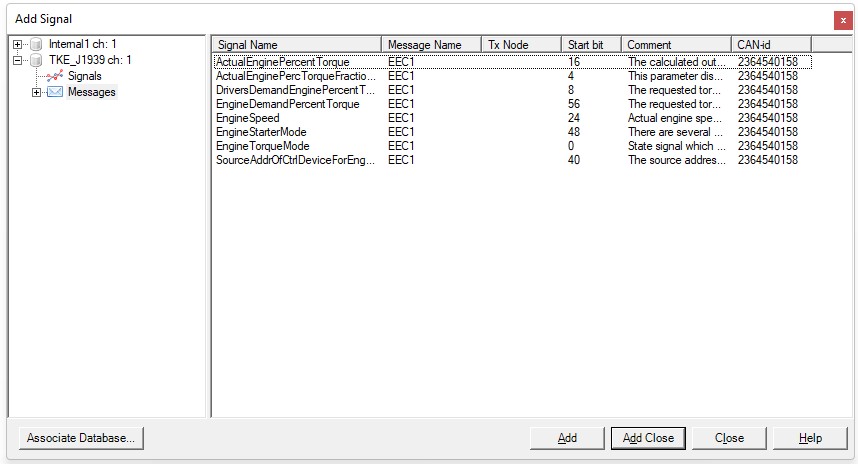

This dialog box allows adding signals to the Configure signals window, which in turn allows monitoring their runtime values in the Data tab and the Graph tab. Once one or more databases have been associated with the project, all the signals and messages in those databases become available in the tree-view on the left side.

The figure and the table below illustrate the graphical layout of the Add Signal dialog box and the buttons available to the user.

Figure 3.4 Add Signal

Table 3.1 Add Signals Form Description

| Name | Description |

| Associate Database… | Associated Database |

| Add | Add selected signals from signal list. |

| Add Close | Add selected signals from signal list and close the dialogue |

| Close | Discard list of signals and close the dialogue |

| Help | Open the Add Signal section in the help document |